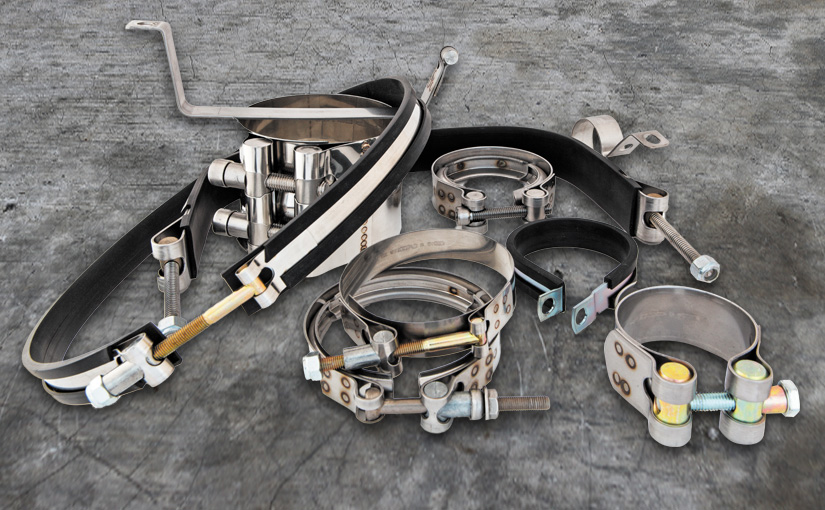

Straps can be manufactured in a variety of designs and we can also offer a wide range of securing bolts, although the most popular is our T-Bolt Style ‘T100’ which, being captive in a slotted loop, can swivel through more than 100° and thus eliminate the risk of fracture through vibration. There are over 50 different configurations of fastener types currently manufactured with the number continually rising as we continue to develop styles to satisfy customer requirements. Some of our more popular styles can be seen on this page.

As with all our products the straps can be manufactured using a number of different materials such as AISI304, AISI316, AISI316Ti, Carbon Steels (various plating & powder coating available), titanium & Inconel. Nitrile extrusions can also be applied to reduce vibration and protect even the most delicate of applications.

There is no restraint on the length of strap produced, for certain applications some styles can be joined together to produce the desired length.

Click the image thumbnail to view full size

In addition to our existing ranges, Neophix are equipped to produce special purpose Tank Straps to meet customers’ individual requirements. Our Design Engineers have many years experience in the industry and are always available to give customers advice on the design of clamps for individual applications.

Click the image thumbnail to view full size

DOWNLOAD TANK STRAPS STYLES PDF

| Grade | Tensile Strength (Mpa) min | Yield Strength 0.2% Proof (Mpa) min | Elongation (% in 50mm) min | Hardness Brinell (HB) max | Why Use? |

| 304 / 1.4301 | 515 | 205 | 40 | 201 | Excellent forming & bending characteristics, great corrosion resistance. |

| 316 / 1.4404 | 485 | 170 | 40 | 217 | When higher resistance to pitting and crevice corrosion is required,in chloride environments. |

| 321 / 1.4541 | 515 | 205 | 40 | 217 | When higher resistance to temperatures of around 600-900°C is needed. 321 has higher hot strength. |

| 316Ti / 1.4571 | 500 | 200 | 40 | 215 | Titanium stabilised grade 316, when a higher operating temperature and resistance to pitting and crevice corrosion is required. |